DENOPI project

The DENOPI project (ANR-11-RSNR-0006) aims to acquire experimental data on the physical phenomena associated with a spent fuel pool loss-of-cooling and loss-of-coolant accidents. Launched on December 1st 2013 for a period of six years, the project consists of a number of experiments whose results will serve as a basis for model development and validation of numerical simulation tools. DENOPI is one of seven IRSN projects selected by the National Research Agency (ANR) in response to the RFP for "Nuclear safety and radiation protection-related projects" issued in 2012.

Context and objectives

Located in the fuel building, the spent fuel pool is used to store spent nuclear fuel until the residual power[1] is sufficiently low to allow for final disposal away from the site. The spent fuel pool is also used to temporarily store fuel during reactor outages.

Loss of spent fuel pool cooling or coolant (for example, in the event of a spent fuel pool cooling pipe break or pump shutdown, as was the case at Fukushima) can , in the long term, lead to fuel uncovery and heatup. If no appropriate measures are taken, fuel rod cladding oxidation by air and steam will cause an exothermic runaway reaction leading to fuel rod degradation and release of radioactive materials.

Despite the significant time available before fuel uncovery, the Fukushima accident has demonstrated the difficulty of implementing appropriate measures to resume safe operation and ensure proper cooling of the Spent Fuel Pool. It is therefore important to better understand the evolution of this type of accidents so as to evaluate the relevance of measures taken to prevent the risk of fuel uncovery and mitigate its potential impact.

With this end in view, IRSN has launched the DENOPI project.

Project outline and research themes

The DENOPI project is structured around three research themes:

Theme 1: Large convective structures within the spent fuel pool

This research theme investigates the thermal-hydraulic behavior of the spent fuel pool as a whole, under conditions representative of the various phases of a loss-of-cooling accident: temperature rise, boiling, recovery of cooling capability.

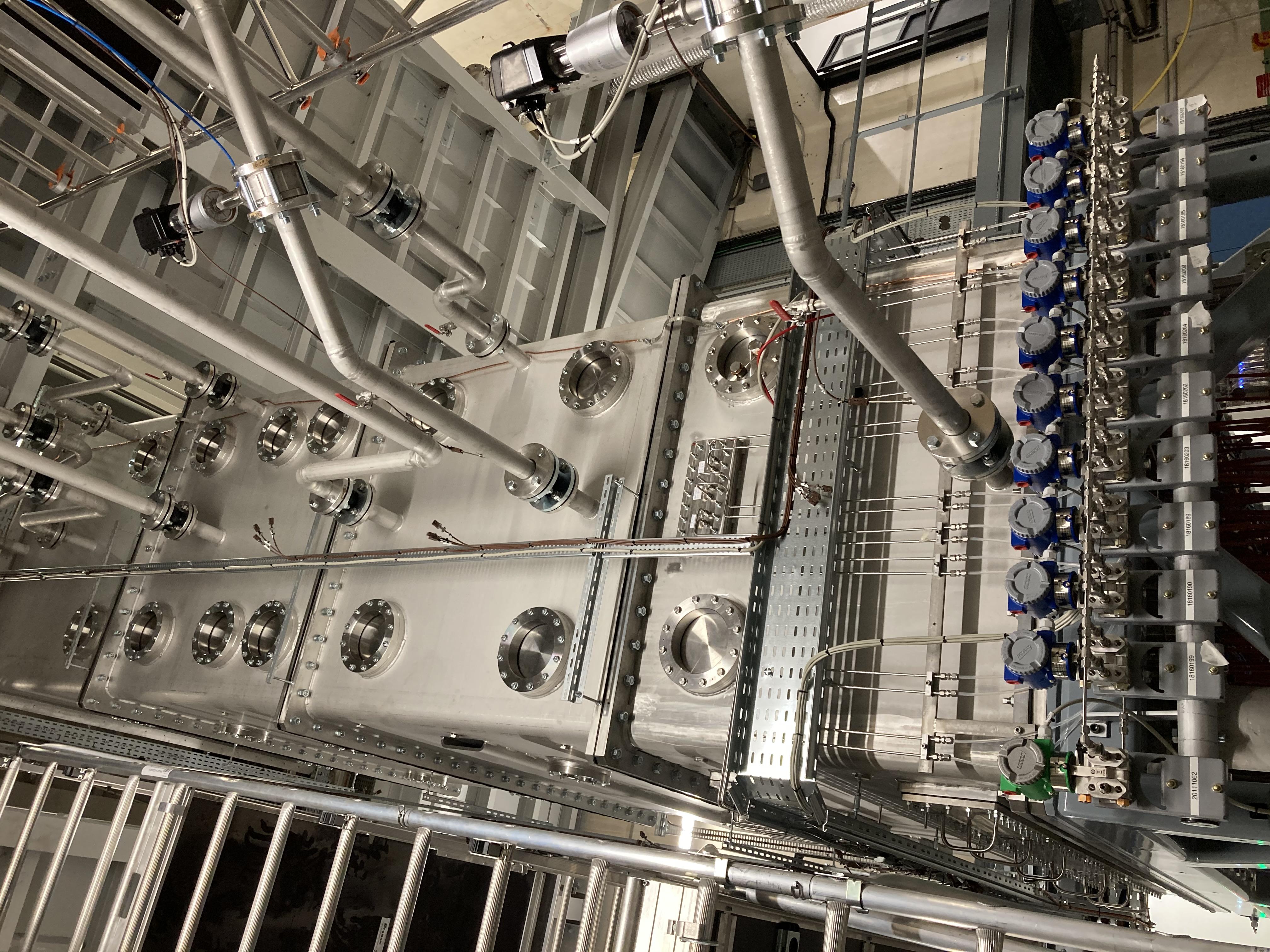

Natural convection and boiling phenomena will be simulated on a small-scale spent fuel pool mockup. Temperature and velocity measurements taken in the region above the fuel assembly storage cells will be used to characterize convective flows and subsequently provide a basis for validation of numerical simulation tools. Its manufacture was finalized at the end of 2020. Qualification testing began in January 2021 to validate the installation. Matrix testing will begin in mid-2021.

Theme 2: Fuel assembly thermal hydraulics

This research theme investigates the thermal-hydraulic phenomena occurring within the fuel assemblies, i.e.

- Before fuel uncovery:

The objective here is to obtain experimental data on steam-water two-phase flow and heat transfer within the fuel assemblies (void fraction, velocity field, temperature).

- During fuel uncovery:

The objective here is to better understand the thermal-hydraulic behavior of the fuel assembly in water-covered and uncovered regions, particularly so as to determine those conditions under which there is a risk of air ingress into the fuel assembly. This is of particular importance, since air ingress could cause a runaway cladding oxidation reaction in the uncovered region (the oxidation kinetics with water vapor alone are slower in the absence of air) and compromise all possibility of cooling the fuel assembly before it is degraded. The effectiveness of using water spray to cool the fuel assemblies will also be investigated.

Tests are scheduled for 2015-2017. After initial testing on small-scale mockups, full-scale tests will be conducted on an electrical fuel rod simulator assembly (simulating the thermal behavior of nuclear fuel rods) placed in a spent fuel pool storage cell.

Qualification testing is underway. The tests of the matrix, (validated with the partners) started in January 2021.

Theme 3: Zirconium cladding oxidation by air/steam mixture

This research theme focuses on the investigation of cladding oxidation phenomena at high temperature in a gaseous atmosphere containing oxygen, nitrogen and water vapor. The detailed kinetic data obtained will allow for better assessment of available safety margins before runaway conditions occur.

In contrast to previous studies conducted on the subject by IRSN and other laboratories, the emphasis here is placed on the potential effects associated with the presence of an oxide layer formed by water corrosion on the cladding surface, and with the presence of water vapor and air in the gaseous atmosphere surrounding the cladding in the event of fuel uncovery.

In addition to oxidation kinetics data, this research is also expected to provide information on the mechanical resistance of significantly oxidized cladding in the event of an accident that could have been mitigated before fuel rod destruction. This information will be used in particular to assess the feasibility of post-accident fuel handling for subsequent disposal.

Tests campaigns are scheduled for 2014-2016 at IRSN and partner laboratories. This work is the subject of two post-doctoral research internships and a thesis project.

A review publication appeared in Journal of Nuclear Materials in October 2018.

Perspectives

The DENOPI project will be finalized at the end of 2021 with a first harvest of scientific results. This is a first step to study the problem of pool dewatering. At the same time, there is a consensus on the existence of important physical phenomena during a pool accident[2]. The IRSN plans to develop these large-scale experimental facilities and will propose an international program for 2022-2025.

[2] See OECD work on the state of knowledge (May 2015, June 2017)